While in the molten or liquid state it is poured into a mold or vessel to create a desired shape. In some eras and in some industries the foundry was given the drawing of the finished part and they create a drawing of what the finished casting should look like and of course the pattern needed to create the cast part.

How To Design Drawing For Investment Casting

Any post-casting machining will be only to add in tightly toleranced features or other finishing details.

. Typical section from a drawing showing casting datums. Figure G4 Part 7 Casting File We select the Inventor icon in the upper left corner of the Inventor 2012 window and we select Save As from the drop down menu. Casting is one manufacturing process.

To summarize machining is ideally used for prototyping small quantity runs precision tolerances and components with large complex volumes. Die casting is a near-net-shape process. This will take a fraction of the time of machining a billet from solid.

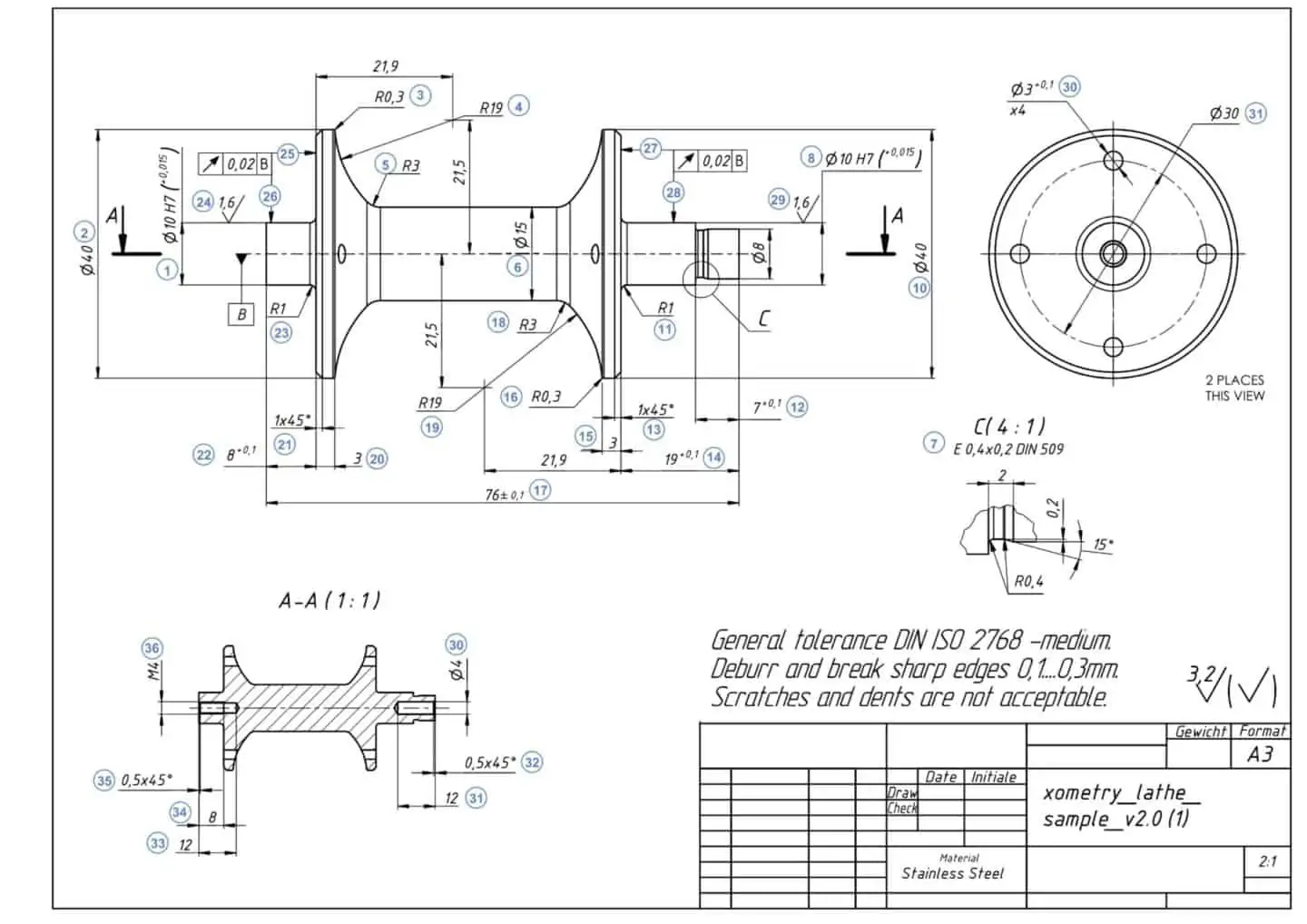

Much of the machine work is done in house with our Atrump CNC milling machine and our Clark lathe. Figure 1 - Drawing indications see clause 4 1 Licensed to ASSOC. Part drawings and assembly drawings belong to this classification.

Machining is just one manufacturing process. This mould is built in accordance with the desired object as the inverse profile of the mould is. A shop cast a set of parts I designed.

Use the axis to pattern around and that will be the center of the tree. Not all the castings we make are purchased as a raw casting. Go and generate an axis and make a pattern.

Ideal Applications for Machining and Molding. The finish machine drawing only shows dimensions for a few features that get machined such as bores. Assembling joining of the pieces is done by welding binding with adhesives riveting threaded fasteners or even yet more bending in the form of a crimped seam.

Forging is the application of thermal and mechanical energy to steel billets or ingots to cause the material to change shape while in a solid state. The Single Source Advantage. Forging Drawing vs Machining Drawing.

To indicate desired casting smoothness a note like the one at left should be provided in the list of drawing notes. There are many others as discussed below. Ideal Applications for Machining and Molding.

Figure G4 Part 7 Casting File We select the Inventor icon in the upper left corner of the Inventor 2012 window. Structural steel and sheet metal are the usual starting materials for fabrication along with the welding wire flux. Machinists generally use precision machine tools such as lathes boring machines milling machines and cylindrical or surface grinders to shape materials such as steel brass iron bronze aluminum titanium and plastics and to manufacture components to meet customers specifications.

A machining detail drawing provides. The cast surfaces are located to the cast datums XYZ. This is a government job and the technical data package allows the option of making the part from the forging or 17-4PH bar stock.

The oldest manufacturing process where the raw material is first melted poured into a pre-built mould and subsequently allowed to cool down. Casting is the process where metal is heated until molten. Casting and Machining are Complementary processes to each other in investment casting.

Im in the midst of dealing with such an issue from the other end. Right-click and choose Float. Subsequent machined features such as the threaded hole are located back to the machined datums.

Cast molding is great for large quantity runs exactness from lot to lot and parts where a skin or detailed texture is important. We name the file Part 7 machining and push the Save button. --- Raw casting basic dimension 1.

Datums should be made from physical. The machined datums are also located to the cast datums. The process is fast and repeatable.

Depending on the needs of the customer Decco also provides machined andor painted castings. Machining sensitiviy analysis for both options change in total income had the most effect 20 change in income resulted in 30 change in present value highlow for casting electricity was significant as well larger amount higher significance salvage least signigficant sensitivity analysis conclusion we chose the machining process equipment cost. Click on the part which is fixed.

The surface smoothness required shall be expressed by a numerical surface roughness-height-rating RHR in micro inches. Tmoose Mechanical 27 Jan 12 1245. The component you want to capture is the golf club.

Because most prints will not have enough datums to even approach the 24th letter of the alphabet X the last 3 are used to designate casting datums. Consider the figure below. Its easy to get confused about how to stack from a cast surface to a machined feature.

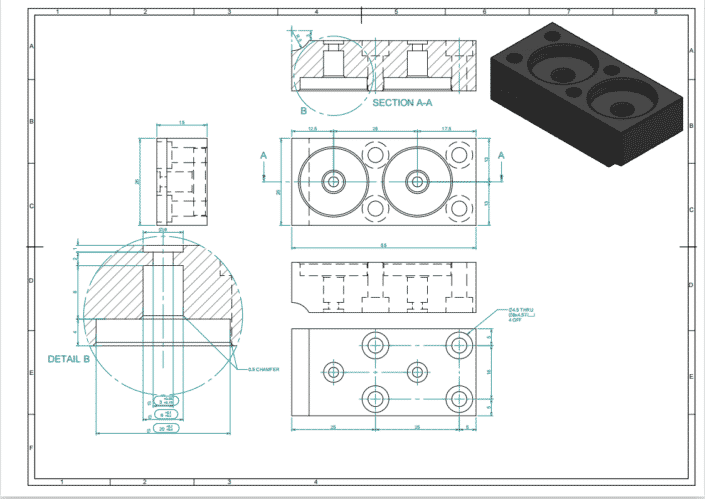

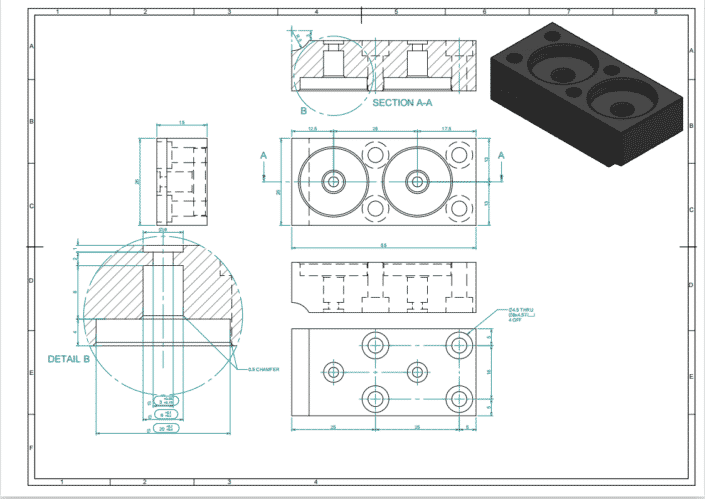

Dimension of a raw casting before machining see figure I the necessary ma- chining allowance being included see figure 2. Figure G5 Part 7 Machining We then can close the Part7 drawing and open the. This technical drawing shows the machine parts assembly using joining by threaded fasteners.

Classifications of Drawings 41 Machine Drawing It is pertaining to machine parts or components. They are typically designated as X-Y-Z or Z-Y-X. There are two types of machine drawing.

To do a stack between. We create higher assembly part numbers from our castings usually changing the. Difference between casting vs forging.

We see our casting drawing and we will save the file as Part 7 machining. It is presented through a number of orthographic views so that the size and shape of the component is fully understood. Machining Drilling 008 -003mm Milling 008mm Turning 005mm Abrasive processes Grinding 0008mm Lapping 0005mm Surface finish roughness Casting Die Casting Good 1-2µm Investment Good 15-3 Sand Casting Poor 12-25 Metal forming Cold rolling Good 1-3 Hot rolling Poor 12-25 Machining.

Forging is the application of thermal. This where casting datums come into play. So if you are casting rather than machining then you use only use the material needed.

That will allow you to grab the part and drag it around in space. If the finish symbol is used on the field of the drawing stock will be allowed for machining.

15 Detail Drawings Permission Granted To Reproduce For Educational Use Only Explain Terms And Standards Related To Various Types Of Drawings Used In Ppt Download

How To Prepare A Perfect Technical Drawing Xometry Europe

Cast Iron Product Drawing And Renderings Help Facilitate The Iron Casting Purchasing Process

The Casting Process Of The Enclosed Switchgear Outer Body Casting Download Scientific Diagram

Solved 2 A Choose An Appropriate Casting Process Chegg Com

Technical Drawing For Cnc Machining Runsom Precision

The Bearing Bracket Casting Part Drawing Download Scientific Diagram

0 comments

Post a Comment